One product that has garnered increasing attention in the past two decades is collagen. Low-cost by-products such as fish skin and scales can be converted into collagen-based products, which have high added value potential for use in various health-related sectors, such as food, medicine, pharmaceuticals and cosmetics, and low environmental impact.[1] The marine collagen market is estimated to reach US$1,040 million by 2026. In addition to fish, jellyfish and sponges also have high levels of collagen which can feed the same market for ‘marine collagen’.

Methods are well established to extract collagen, with variations to address differences for the part of the fish (e.g. scale vs bone) and species-specific differences. Compared to collagen derived from bovine and porcine sources, marine collagen is considered safer, because it is less likely to trigger an immune response or transfer disease, and is free from religious concerns.[1, 2] Another benefit is the bioavailability, as collagen from aquatic sources currently employed in healthcare and food sectors is predominantly type I collagen, mostly derived from fish scales and skin. Type II collagen can be obtained from fish cartilage (e.g. shark cartilage), while type IV collagen can be extracted from marine sponges and some jellyfish.[1] Marine collagens also typically have a lower melting temperature, which makes them easier to digest.

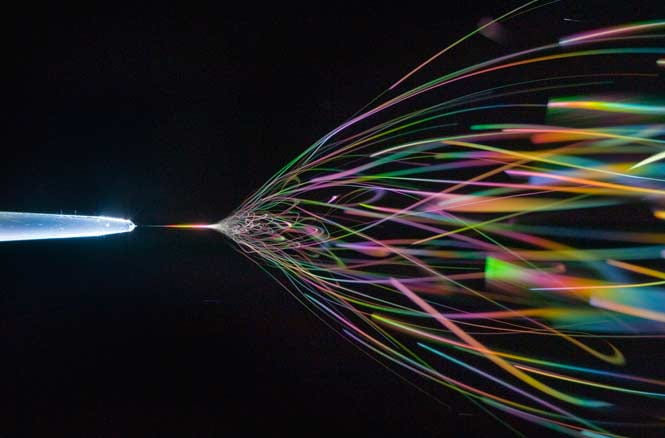

Electrospinning nanofibres from hoki skin. Image credit: Plant & Food Research/Robert Lamberts.

When Sanford first began to look beyond commodity fisheries products to more premium products, they saw a gap in the market. There was unmet demand for collagen, specifically high-quality sustainable collagen products. Because collagen is an abundant protein found throughout fish, the company had good supply from their various fisheries. Deciding on the source and specific products was the first challenge.

The company contacted Aotearoa New Zealand’s CRIs in search of expertise, which led them to connect with researchers at Plant & Food Research who had developed the novel extraction methods and processing technologies to extract collagen from hoki skin. Sanford had quota for hoki. This spawned the use of a single waste stream from a single species to make premium collagen products.

The first product came about through collaboration with Revolution Fibres and a technique called electrospinning. This technique transformed the skin into nanofibre 500 times thinner than human hair, which could be made into high-value collagen beauty products that are instantly absorbed into human skin. The novel product is a dissolvable cosmetic collagen patch made from hoki skin called actiVLayr.

The next product soon to reach the market is a cosmeceutical hydrolysed collagen product which is both odourless and flavourless.

The key considerations in the product development process that ensured a high value for these collagen products were:

- Medical approval. It takes a significant investment in clinical research to meet regulatory requirements for clinical claims but being able to make the claims means that products will be able to be marketed as speciality high-value products and businesses will be able to charge more.

- Single source. Extracting collagen only from the skin of a single species is easier to market as a pure product which draws a higher value. This is strengthened by being fished from Aotearoa New Zealand’s waters which are viewed as pristine in many overseas markets.

- Sustainability credentials. From a marketing perspective, hoki was suitable as being MSC-certified and QMS-managed gave credibility to sustainability claims.

Using hoki skins to create high-value collagen products aligned with Sanford’s goal to make premium products out of commodities in a sustainable way. Sanford’s experience shines a light on some of the hurdles faced in developing high-value products and how to overcome these. The broader fisheries industry in Aotearoa New Zealand could learn from these experiences to expand the premium products offered from our fisheries industry.