Case studies

Listed below are the cases studies found in our web resource entitled “What can I do with my food waste?”. Click on a box to expand the case study and read all the details.

Animal feed from food waste in Aotearoa

Food waste is transformed to animal feed by a number of companies in Aotearoa, including Ecostock, Castlegate James, and Takanini Feeds, which produce feed for the agricultural sector, and Omega Plus and United Fisheries, which produces treats and dietary supplements for pets. Direct relationships between food businesses and local farmers is another pathway from food waste to animal feed, and households often feed scraps to their pets too.

For animal feed businesses in Aotearoa, feedstocks, processes, and products vary. Overall, there is a focus on production of animal feeds from homogenous, pre-consumer food waste streams, rather than mixed household or food service food wastes. This focus is driven by the need to minimise potential disease transmission, comparative ease of process control and increased certainty around feed safety and nutritional properties that comes from knowing exactly what is going into the feed.

Ecostock, for example, specialises in de-packaging manufactured food products at risk of going to waste and converting them into food waste blends to be used in stock feed. Castlegate James and Takanini Feeds, meanwhile, produce finished feed products, combining food waste-derived ingredients such as biscuit meal and brewers’ grain with other ingredients, making feed mixes and pellets. Across Australia and New Zealand, Castlegate James converts 700,000 tonnes of food at risk of going to waste to animal feed every year. Commercial fisheries in Aotearoa convert by-products (e.g. offal) to fish meal, which can be used as feed for chickens, pigs, and farmed fish. Omega Plus demonstrates how more financial value can be gained from animal feed conversion of fisheries by-products by catering for the premium pet food market, as do United Fisheries in making mussel-based nutritional tablets for pets.

Opportunities to convert inedible and unpreventable food waste streams to animal feed continue to be explored in Aotearoa, such as use of milk processing waste, crop residues, and grape marc as feed components.

Another less-explored avenue is conversion of mixed household and food service food waste to animal feed. The main concerns associated with using post-consumer mixed food waste as animal feed relate to nutrition, transmissible spongiform encephalopathy risks, pathogen transmission, and chemical contaminants. Commercial feed manufacturers have the required processes to comply with biosecurity regulations and apply adequate heat treatment which negates pathogen risks, and nutritional needs of animals can be met with food waste-derived feeds, especially when they are used as part of a wider diet programme. However, current food waste treatment technologies may not eliminate the risk of diseases like mad cow disease (a transmissible spongiform encephalopathy disease) caused by transmissible proteins able to move between animals and humans in the food supply chain. In addition, some chemical contaminants, if present in the food waste feedstock, may accumulate in animal feed. New Zealand’s animal feed rules ban the use of ruminant protein in feed for ruminants given the risk of transmissible spongiform encephalopathy spread, which would mean that any animal feed derived from mixed household food waste wouldn’t be suitable for ruminant animals if it might contain meat.

Ecogas: Anaerobic digestion of food waste

Ecogas is a New Zealand-based company which specialises in the anaerobic digestion (AD) of organic waste from households and businesses. Food waste is used to generate biogas (a fuel source) and digestate (a potential fertiliser). Ecogas, a partnership between Pioneer Energy and Eco Stock Supplies, is new to the AD scene in New Zealand, having recently opened their flagship facility in Reporoa in mid-2022.

Once fully operational, Ecogas plans to process 75,000 tonnes of organic waste at its Reporoa facility – including a mix of household food scraps, commercial and retail food waste, and dairy waste – producing biogas and digestate from these feedstocks. Kerbside food scraps from Auckland as set to make up for 38,000 tonnes of Ecogas’ feedstock as collections is rolled out during 2023. After being collected, this household food waste will be consolidated in Ecogas’ sorting and consolidation centre in Papakura, and then sent to the Reporoa Organics Processing Facility using freight trucks that otherwise would have been empty on their return journey from Auckland to Reporoa. There it will be separated from contaminants like plastic, biodegradable packaging, and metal prior to processing in anaerobic digesters.

Sorting hoppers which receive and filter organic waste streams at Ecogas’ Reporoa plant.

Biogas, the primary product of AD, is a mixture of methane, CO2, and small quantities of other gases. To create biogas, feedstock at Ecogas’ Reporoa facility is machine-sorted, passed through a grinder, and fed into large airtight tanks, where microbes are used to break down organic matter in the absence of oxygen, releasing biogas in the process. Biogas is siphoned out of the top of digestion tanks whereafter it is conditioned (cleaned to remove unwanted sulphur compounds and moisture) and stored for use. Biogas can be used in place of virgin natural gas, providing energy without the environmental tolls associated with natural gas extraction. Concurrently, biogas produced from food waste mitigates methane emissions that would otherwise occur if waste was sent to landfill. Presently, Ecogas generates electricity and heat for their Reporoa facility by burning a portion of the biogas produced on site. Once fully operational, Ecogas plans to send the heat and CO2 from biogas to a local tomato glasshouse to improve growing conditions. Looking forward, Ecogas plans to upgrade the biogas it produces into biomethane to inject into the natural gas grid.

Beyond biogas, the AD process also produces digestate, a wet mixture of processed solids and water. Where digestate is primarily derived from food waste – as is the case for Ecogas – it typically contains high levels of nutrients like nitrogen, phosphorous, and potassium, minerals and trace elements. Given that most of the carbon in the feedstock is converted into biogas, digestate contains little carbon relative to other soil amendment products like compost. At Ecogas, digestate will be pasteurised before being sent to farmers as an alternative to mineral fertilisers. This is a common practice in several European countries, as well as parts of North America and Asia. To help inform the introduction of digestate on the New Zealand farming market, Ecogas has run trials with digestate from at a small pilot plant in Wiri to compare the effects of digestate on pasture growth with common fertilisers and soil treatments, although results aren’t yet available. In addition, Ecogas, in partnership with the Bioenergy Association, is working on an industry-lead set of standards for digestate use and certification in New Zealand. This is a key step in ensuring that there are end markets for digestate, especially as it is currently considered a waste product in New Zealand. Ecogas’ approach to these standards seeks to mirror initiatives abroad (e.g. the PAS110 in the UK and the SPCR 120 in Sweden) which control digestate quality and minimise any potential adverse effects of its application.

Ecogas currently provides fulltime employment for seven people, which will potentially increase to 10–15 as capacity at Reporoa increases. Ecogas plans to expand its operations in Aotearoa in the future, with discussions ongoing for new facilities in Canterbury and Manawatu in the next five years.

The digester tanks at Reporoa which hold up to 3,500,000 litres of organic waste. Methane rises to the top of the tanks

and are captured using a hose system.

FlyFarm: Converting food waste to animal feed in Brisbane

FlyFarm is a growing agri-tech business focusing on developing highly automated black soldier fly (Hermitia illucens) larvae farms that convert organic waste into high quality protein for animal feeds. Insect frass is also produced during bioconversion, which FlyFarm is trialling as a fertiliser.

The company is headquartered in Singapore and has a presence in Hong Kong, Taiwan, and Brisbane. The Brisbane team runs a pilot plant, recently expanded and fitted with robotic handlers, environmental sensors, and software control mechanical shifters, enabling much of the vertical insect farm to be automated.

OPMCSA and Fight Food Waste Cooperative Research Centre visiting FlyFarm, hosted by co-Founder Andres Crabbe,

Queensland FlyFarm manager Oliver Warcup, and entomologist Chen Wu, alongside the FlyFarm robotics team.

FlyFarm is focused on producing high quality outputs so currently processes homogenous plant-based food waste (e.g. brewers’ grain) rather than mixed waste to avoid contamination of the larvae or frass.

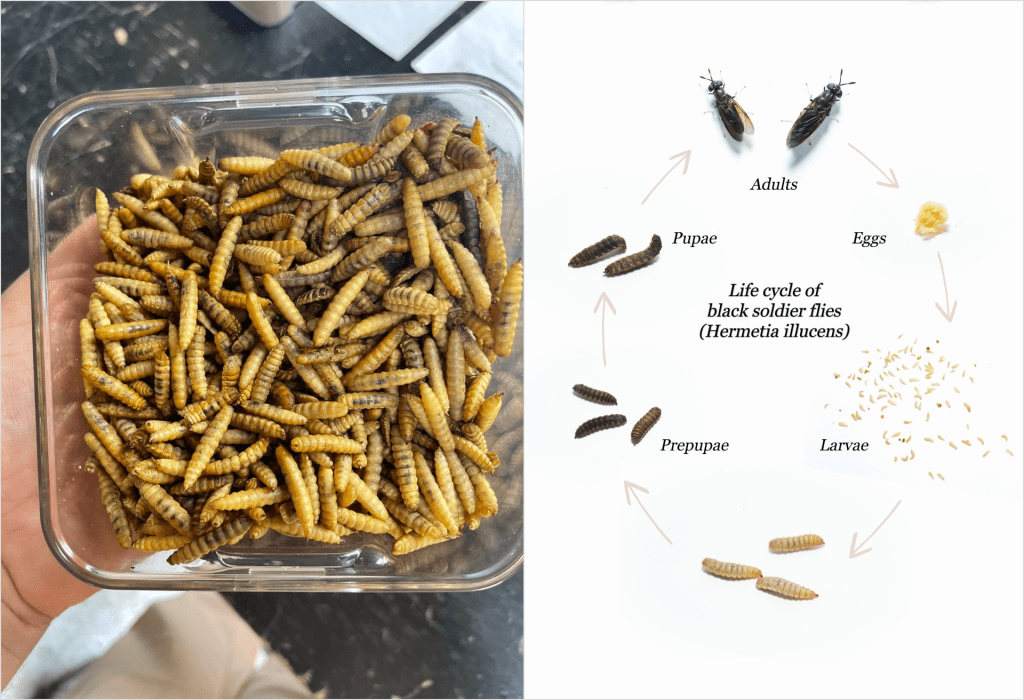

The process begins with adult black soldier flies, which are raised in mosquito net enclosures where they lay eggs. Because black soldier flies are most active during the day, they are kept under UV light to stimulate activity.

The larvae are put into trays and introduced to a soy by-product initially, before being fed on the primary food waste stream, which usually must be ground into small particles to optimise bioconversion. Over the course of 9–11 days, the larvae consume the food waste. FlyFarm works to minimise the residual food waste remaining, so the trays mostly contain larvae and frass at the end of this time.

The larvae are sifted from the frass and blanched and dried before bio-oil is extracted from them (‘defatting’). The protein-rich dried larvae can then be powdered, and the bio-oil and powder (along with other ingredients) can be combined in ratios that meet the nutritional needs of different animals and operational requirements of farmers. This post-processing also stabilises the larvae, giving them a long shelf life, while a live larvae product would have to be used more rapidly (although is offered by some bioconversion businesses, e.g. for captive reptiles). A small number of larvae are kept, maturing into adult flies to repeat the process. When adult flies die, some are combined into an attractant mixture that is used to get live flies to lay their eggs in a collection substrate, while the rest (which have a small total mass) go to waste. FlyFarm intends to explore ways to purify chitin from dead flies and pupae shells in the future (chitin has a range of applications, e.g. as a food additive or emulsifier).

The frass contains nutrients with fertiliser value. It can be further processed (e.g. by composting) or applied directly to fields. FlyFarm is trialling direct application of its frass with a local strawberry grower.

Left to right: Dried larvae produced at FlyFarm; Black soldier fly (Hermitia illucens) lifecycle. Image credit: Chen Wu, FlyFarm.

FlyFarm’s ideal operating model involves partnership with food waste owners, co-locating bioconversion infrastructure at a food processing or manufacturing facility and valorising their waste onsite. FlyFarm has multiple revenue streams – including food waste handling fees, larvae product sales, and frass product sales, and are looking to verify the greenhouse gas emissions benefits of their work so that they can sell carbon credits on voluntary markets.

When establishing in Australia, FlyFarm faced few regulatory barriers as black soldier flies were already reared commercially there, and the species is found globally and not considered to be an invasive species. Focusing on homogenous, plant-based food waste also eases regulatory barriers.

FlyFarm is continuing to refine its processes and undertakes research into a range of topics including selective breeding for flies that efficiently convert food waste, the fate of contaminants during the bioconversion process, and the performance of frass as fertiliser.

Kaicycle: Composting and urban farming

Kaicycle Composting is a subscription-based community composting enterprise which processes 40 tonnes of household and office food waste in Wellington each year. Since it started operating in 2015, Kaicycle Composting has processed an estimated 230 tonnes of food scraps, in addition to arborist waste, coffee chaff, and untreated wood shavings. The resulting compost is used at the Kaicycle Urban Farm in Newtown, and any extra is donated to City Housing and local community gardens. Kaicycle Urban Farm produces fresh vegetables for the local community, with people able to buy a share in the outputs of the farm.

Kaicycle currently uses composting boxes in Newtown and is at capacity, but a new site in Rongotai and an in-vessel composter, which fully contains and automatically stirs compost, will enable Kaicycle to process an additional 90 tonnes of food scraps per year. As capacity grows, Kaicycle will look to sell surplus compost to supplement its income from the urban farm and scraps collections.

Kaicycle collects food scraps from around 200 offices and households, including from groups in multi-unit dwellings where home-based solutions for food scraps are often limited. Collections are done by e-bike, reducing transport-related emissions from Kaicycle’s activities. In addition, about 65 household subscribers drop scraps off at three sites across the city.

Aerial view of the Kaicycle urban farm in Newtown, Wellington. Image credit: Te Kawa Robb, Toroa Creative.

Compost manager Kate Walmsley building a compost pile with collected food scraps.

Liam and Tom, former Kaicycle staff members, collecting food scraps by e-bike in Wellington’s CBD.

Kaicycle uses scales to measure the ratio of nitrogen-rich food waste to carbon-rich garden waste, coffee chaff to regulate water content, and thermometers to ensure compost piles reach at least 55°C so that harmful microbes and seeds are killed. Compost nutrition and contamination testing at Eurofins and Hill Laboratories helped Kaicycle improve its processes when it was getting started, and it intends to do more testing this year to continuously improve its product.

The voluntary compost standard in Aotearoa (NZS 4454) focuses on the chemical composition of compost rather than its biological health (other than a limit on the presence of E. coli, a pathogen), but Kaicycle is keen to understand the diversity and relative levels of beneficial microbes in its compost too, which the standard acknowledges is important for the release of nutrients but doesn’t provide a methodology for. Labs like Soil Foodweb New Zealand which analyse the microbial health of compost and soils are scarce.

Kaicycle works to ensure its subscribers know what to include in their scrap bins. It recently undertook an education campaign explaining why it doesn’t accept any compostable packaging, highlighting that compostable packaging embeds the linear economy and risks introducing contaminants while bringing little to no nutritional value to the compost.

While well-managed compost piles mean odour and pest risks are minimised, Kaicycle works with Predator Free Wellington to support trapping efforts and the wider predator free kaupapa.

Kaicycle employs the equivalent of 4.5 fulltime staff, split across fulltime and parttime roles in the composting, farm, and community engagement arms of the enterprise. Kaicycle also provides many education and community engagement opportunities through public volunteer sessions, community events, workshops, and an urban farm school. The urban farm school is delivered with education provider Papa Taiao Earthcare. In 2023, the urban farm school will have more than 25 local high school students attending a year-long, NCEA accredited programme. In the last year Kaicycle has hosted 125 volunteers at the farm.

Kaicycle hosting local community members at a farm open day with pumpkin soup made from farm pumpkins.

Open days usually include workshops, seedling sales, shared kai, live music, and farm tours.

While all composting leads to some greenhouse gas emissions (albeit substantially less than emissions from landfilling food waste), Kaicycle works to keep methane emissions to a minimum by managing the composition of its compost piles, turning them regularly to ensure they are oxygenated, and inoculating piles with Beneficial Anaerobic Microbes (BAM) like those used in bokashi. BAM contains facultative anaerobes which can continue to break down food scraps in the absence of oxygen without producing methane, with the intention being that if the pile becomes anaerobic, methane-producing bacteria won’t dominate. Using BAM reduces the frequency with which the compost piles must be turned, reducing labour and allowing beneficial fungal networks to develop with less disruption.

As with many district plans, the Wellington District Plan is ambiguous about the legal status of community gardens, urban farms, and community composting. Wellington’s plan is currently being updated and looks to include composting at community gardens as an expected and permitted activity. Kaicycle hopes to see community composting directly included as well, to clarify the status of and rules associated with small- and mid-scale composting enterprises.

Kaicycle is currently undergoing a three-year process to attain Hua Parakore verification for its operations. The Hua Parakore verification scheme is a kaupapa-based approach to organics certification developed by Te Waka Kai Ora, the Māori Organics Authority. Participating organisations must demonstrate how they embed the kaupapa of whakapapa, wairua, mana, māramatanga, te ao tūroa, and mauri in their mahi.

Living Earth: New Zealand's largest compost operator

Living Earth is a New Zealand-based composting business owned by Waste Management. Living Earth has been in operation for more than 20 years, with primary sites in Christchurch and Auckland, and is New Zealand’s largest organic waste to compost operator. Annually, Living Earth’s composting facilities can process over 100,000 tonnes of garden and food waste, turning it into compost. Compost is sold as a soil amendment, used by gardeners, farmers, and landscapers to improve the fertility, structure, and water retention of their soils.

Living Earth’s composting operations differ between its two sites. At its Organics Processing Plant in Bromley, Christchurch, Living Earth composts 60,000 tonnes of mixed garden waste and food waste annually in 18 in-vessel composting tunnels, generally at a carbon-to-nitrogen ratio of 30:1. Much of this waste is collected from households in Christchurch, as part of the city’s organics kerbside collections. Once organic material is shredded, it is placed in windrow tunnels for 2–3 weeks before being moved outdoors and offsite for maturation to manage odour. During maturation, organic material is broken down by microbes over the course of 2–3 months. During this process, the microbes are kept active and efficient by ensuring that air, temperature, and moisture levels remain consistent within composting material by mechanically turning the windrows and adding water as needed during summer months. Water runoff from the windrows is managed using a pond system. Typically, composting material at Living Earth sits at 50–60°C (a result of the metabolic process of microbes), temperatures which help kill off pathogens and weed seeds in the organic material. Compost from the Bromley site is primarily sold in bulk to farmers in the Canterbury region, as well as local gardeners and Christchurch City Council for restoration projects.

In Auckland, Living Earth runs an outdoor windrow composting system on Puketutu Island, a site which spans 12 hectares (eight of which are currently used for open-air composting, with 4 hectares set aside for potential expansion). At its Puketutu site, Living Earth processes 30,000 tonnes of green waste annually, sourced from yard trimmings and plant material, primarily from waste transfers stations and residential collections. It takes microbes 3–4 months to break down green waste and convert it into compost. As composting operations at Puketutu are outdoors, up to 200 cubic meters of water is added to windrows per day in summer months to maintain moisture content in windrows. Water and leachate runoff is diverted to large storage ponds. Once compost at Puketutu has fully matured, it is mixed with angular sand, pumice, and aged bark to improve its properties as a soil amendment product. This compost product is primarily sold into the Auckland urban landscape market, both in bulk and in bags, as well as to infrastructure projects in and around the region.

Windrows of composting material at Living Earth’s site on Puketutu Island

Compost sold from both of Living Earth’s facilities meet voluntary New Zealand standards for compost, soil conditioners and mulches, while some of their products are certified for use in organic production by BioGro or AssureQuality.

Living Earth works to mitigate several challenges which often affect large-scale composting. For example, micro-contaminants, including heavy metals and herbicides like clopyralid, can reduce the quality of compost. At Living Earth, batches of compost are tested regularly on- and offsite for micro- and macro-contaminants, nutrient value, maturity, and growth performance. During the composting process, Living Earth also monitor and control process parameters, especially temperature, moisture, and oxygen. This ensures that compost undergoes pasteurisation and prevents windrows from becoming anaerobic and producing methane.

Living Earth currently employs 13 staff in Auckland and 18 in Christchurch. Beyond its business activities, Living Earth sponsors a restoration project on Motutapu island and supports a number of community initiatives.

OPMCSA’s George Slim (left) and Living Earth’s Logan Dingle (right) stand in front of piles of mature compost ready for market.

A compost screening machine stands to their right.

Mynoke: The team of three billion

MyNoke is a New Zealand-based vermicomposting business that uses earthworms to process dairy waste residues, food waste, paper and cardboard waste and wastewater sludge, wood ash and other feedstocks at multiple sites across the North Island. MyNoke was started by soil-scientist Michael Quintern in 2007 and today has sites in Ohakune, Taupō, and Tokoroa. Across these sites, MyNoke estimates some three billion worms eat 160,000 tonnes of organic waste annually, converting it into vermicast. Vermicast is primarily used as a soil conditioner to improve fertiliser efficiency and substitute some synthetic fertiliser.

To produce vermicast, trucks collect various organic waste from customers and unload it onto concrete slabs at MyNoke’s vermicomposting sites. Here, the waste is sorted to remove contaminants such as plastic, glass, wood, and plastic lined cups. Organic waste is then mixed with fibrous, carbon-rich materials (e.g. newspaper, egg cartons, sawdust, or cardboard) and laid out on fields in long piles (called windrows) using agricultural machinery. The first of these windrows are seeded with worms (typically Eisenia fetida and Eisenia andrei). As the worms eat their way through waste, they reduce its volume up to 80% and leave behind vermicast. In addition, worms keep the windrows aerated as the move through the pile, helping soil microbes to break down waste further. Once the worms have eaten through the organic waste in one windrow, they migrate to the next windrow in line. A single windrow, which can contain more than 100 tonnes of organic waste, is typically processed by worms and soil microbes within 9–12 months. Vermicast is harvested from windrows annually and is mechanically screened to remove remaining physical contaminants like stones and plastic.

Earthworms are put into a mixed feedstock of biosolids (black and dark brown material), dairy wastes (orange),

and paper pulp (grey) on the concrete slab where MyNoke mixes their inputs. Feedstock mixes like this

are subsequently laid out in large windrows on fields.

The nutrient content of vermicast depends on the feedstock used, but vermicast generally contains high amounts of water-soluble nutrients like nitrogen and phosphorous. Earthworms can remove pathogens (e.g., fungi, aerobic bacteria, and viruses) as they consume organic waste, and vermicast can be further pasteurised using geothermal heat to kill off weed seeds. Unlike composting, windrows do not reach high temperatures, instead maintaining temperatures below 35°C. A benefit of the lower temperature is that it reduces odour emissions from windrows. To protect soils, Mynoke rotates the location of its windrows across paddocks to mitigate soil compaction and prevent the accumulation of excess nutrients.

The majority of MyNoke’s vermicast is sold in bulk to farmers and orchards in Aotearoa, with a smaller share sold to retailers as packaged product for home gardeners. Although vermicast sold to New Zealand markets is not pasteurised, it meets the voluntary New Zealand standard for compost, soil conditioners, and mulches (NZS 4454). When MyNoke’s vermicast is on the international market, it is pasteurised by steaming it to 72°C for a couple of hours before it is tested and shipped overseas.

MyNoke currently employs 30 staff across its three vermicomposting sites on the North Island. The company is planning to expand, with several new sites planned for the North and South Island. In total, MyNoke has a growth goal of 16 sites across New Zealand and further expansion into Australia.

OPMCSA staff member Jacques with MyNoke’s General Manager Phil Holland standing in front of a freshly

harvested pile of vermicast at MyNoke’s Taupō site.

Pyrocal: an Australian gasification company

Queensland-based Pyrocal is an Australian company that specialises in the gasification of residual waste. Pyrocal began developing its technology in 2008, and its flagship project started operating in 2022 – a gasification facility in Loganholme that processes biosolids produced at the Logan City wastewater treatment plant.

Instead of spreading biosolids on agricultural land, as was the city’s previous practice, biosolids are gasified at the wastewater treatment plant. Land spreading of biosolids is receiving increasing scrutiny in Australia given the introduction of PFAS to soil, a persistent organic pollutant which is reportedly broken down by Pyrocal’s gasification technology, as well as the transport emissions accrued when biosolids produced in cities are transported to rural areas.

Because biosolids are so wet, requiring energy-intensive drying before gasification, the process is energy neutral, with no surplus energy being produced. However, gasification reduces the volume of biosolid waste by up to 90% and produces biochar which can be partly or fully recovered, depending on the waste feedstock and char composition. The biochar can be applied to soil, stably sequestering carbon and serving as a soil conditioner. Given its adsorptive properties, biochar also has applications in environmental remediation and as a stockfeed. Pyrocal also gasifies agricultural and forestry residues which, in Loganholme, it uses to get the gasification system up to temperature before processing biosolids.

In addition to its operational facility in Loganholme, Pyrocal has a facility in Wellcamp, where it is developing knowledge about the use of its gasification technology for other feedstocks, including food and green waste.

Pyrocal’s gasification facility at Loganholme (background) next to two wastewater treatment

ponds (foreground). Image credit: Pyrocal.

Biosolids from wastewater treatment following drying (left) and gasification (right).

Pyrocal also undertakes projects exploring the properties and performance of its biochar, including contributing to a recent project with Dubbo Regional Council where it was found that biochar, used as part of a rock pit tree planting system, contributed to enhanced tree growth and reduced need for watering given its water retention and cation exchange properties.

The most complicated part of Pyrocal’s process is air pollution control. It must make sure that particulate matter, sulfur dioxide, nitrous oxide, and other emissions are kept within legal limits. Continuous emissions monitoring and full air emissions analysis during trials enabled Pyrocal’s air pollution control processes to be finetuned to ensure compliance while also improving energy efficiency. The water used in the process of air pollution control is used to quench biochar before being returned to wastewater treatment ponds, and the small amount of soot produced by the system (approximately 200 kg per year) is disposed of as general waste.

Pyrocal sells carbon credits based on biochar produced from nutshells and wood waste on voluntary carbon markets. This is facilitated by Puro.earth, a carbon crediting programme specifically focused on credits for engineered carbon removal and long-term sequestration. Selling independently verified carbon credits on voluntary markets provides an additional revenue stream on top of waste processing fees and biochar sales.

OPMCSA staff member Emily with Pyrocal’s Cherie Pugh (manager) and Durell Hammond (director), and Downer’s

Mark Newland (principal process design engineer) following a tour of the Pyrocal gasification plant at Logan Water.

Date released: 29 March 2023

Last updated: 29 March 2023